Changxing Refractory,Refractory Brick,Castable,Ladle Nozzle,Calcium Silicate,Silicon Carbide

Web: www.yilongrefractory.com E-mail: sales8@chinaelong.com Professional refractory products manufacturer from China since 1978, deals on exploration, whose products have been exported to more than 20 countries. Product portfolio covers shaped and unshaped products, such as fire brick, impact plate, ladle and tundish nozzle, calcium silicate board and pipe, ceramic fiber, slide gate, repair, construction and casting mortar and mixes, etc.

2023年4月10日星期一

2023年3月31日星期五

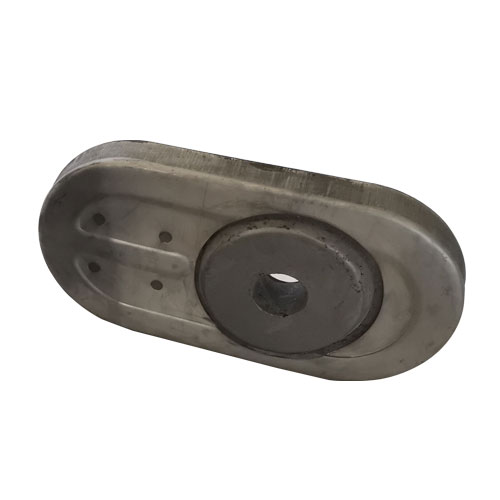

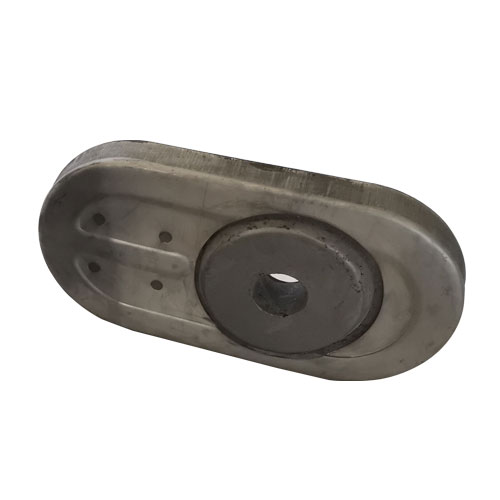

Slide Gate Plate, Ladle slide gate plate

Slide Gate Plate, Ladle slide gate plate

Ladle slide gate plate is an essential component in the steelmaking process. It is used to control the flow of molten steel from the ladle to the tundish in the continuous casting process. The slide gate plate is a refractory material that is designed to withstand high temperatures and mechanical stress.

Source:

Email: info@cxfirebrick.com

2022年2月21日星期一

2022年2月18日星期五

Refractory Materials Supplier, Refractory Products, Magnesia Refractory Material, Furnace Refractory - CX Refractories

Refractory Materials Supplier, Refractory Products, Magnesia Refractory Material, Furnace Refractory - CX Refractories

Refractory Materials Supplier, Refractory Products, Furnace Refractory

2022年2月14日星期一

2021年10月14日星期四

订阅:

博文 (Atom)

Refractory Material, Fire Bricks, Refractory Manufacturer, China Refractory - CX Refractories

Refractory Material, Fire Bricks, Refractory Manufacturer, China Refractory - CX Refractories

-

blast furnace refractory lining material 1.Temperature. The damaged performance of high temperature to fire brick: (1)Erosion. When t...

-

Refractory Material, Fire Bricks, Refractory Manufacturer, China Refractory - CX Refractories

-

Company News | Xinmi Changxing Refractory Co.,Ltd