Chrome Corundum Abrasion Resistance Prefabricated Part for Heating Furnace

The products are produced by corundum and chromium oxide as main materials, formed from casting, after being treated under high temperature, it has high hot strength and good wear resistance, suitable for making the slide rail part of heating furnace.

Content source:

http://www.yilongrefractory.com/AllProductOneServlet?id1=1&id=11

E-mail:sales8@chinaelong.com

Web: www.yilongrefractory.com E-mail: sales8@chinaelong.com Professional refractory products manufacturer from China since 1978, deals on exploration, whose products have been exported to more than 20 countries. Product portfolio covers shaped and unshaped products, such as fire brick, impact plate, ladle and tundish nozzle, calcium silicate board and pipe, ceramic fiber, slide gate, repair, construction and casting mortar and mixes, etc.

2016年12月22日星期四

2016年12月12日星期一

Effect of High Alumina Cement on Refractory Castables

In order to obtain early high mechanical strength, ordinary refractory castable tend to have a higher proportion of cement content (10% to 15%, weight ratio), but this also resulted in a series of refractory castable performance decline, the reason is:

1, in order to complete the hydration of cement, mixing excess water (10% ~ 15%) caused by ceramic refractory castable porosity was high, the density decreased.

2, Calcium aluminate hydrate has strong dehydration and recrystallization effect in the middle temperature stage, destroying the structure of the hard spots in the castable, so that the strength of the castable refractory material in the middle temperature phase drops sharply.

3, cementitious binder will be more into the castable, leading to ceramicized refractory castable load softening temperature decreases, thermal shock stability performance deterioration. In view of the poor performance of ordinary refractory castable, the low cement insulating castable is effective to avoid the high temperature performance. The so-called low-cement refractory castables, the cement content of less than 8%, while less than 4% is called ultra-low cement refractory castable. In contrast, the ordinary refractory castable above mentioned shortcomings, are converted into low-cement castable materials advantage. Its structure is dense. Low porosity, high refractoriness, load softening temperature is high, high temperature strength, thermal shock stability. However, due to its low content of cement, resulting in a long condensation time, low early strength in winter and low temperature conditions, especially in the construction of negative. Therefore, in the masonry, to give full attention

1, in order to complete the hydration of cement, mixing excess water (10% ~ 15%) caused by ceramic refractory castable porosity was high, the density decreased.

2, Calcium aluminate hydrate has strong dehydration and recrystallization effect in the middle temperature stage, destroying the structure of the hard spots in the castable, so that the strength of the castable refractory material in the middle temperature phase drops sharply.

3, cementitious binder will be more into the castable, leading to ceramicized refractory castable load softening temperature decreases, thermal shock stability performance deterioration. In view of the poor performance of ordinary refractory castable, the low cement insulating castable is effective to avoid the high temperature performance. The so-called low-cement refractory castables, the cement content of less than 8%, while less than 4% is called ultra-low cement refractory castable. In contrast, the ordinary refractory castable above mentioned shortcomings, are converted into low-cement castable materials advantage. Its structure is dense. Low porosity, high refractoriness, load softening temperature is high, high temperature strength, thermal shock stability. However, due to its low content of cement, resulting in a long condensation time, low early strength in winter and low temperature conditions, especially in the construction of negative. Therefore, in the masonry, to give full attention

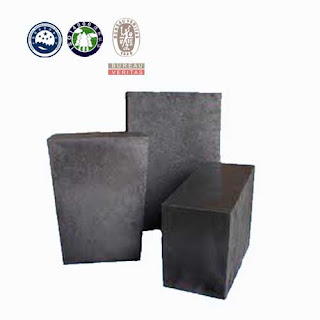

Magnesia Alumina/Alumina Magnesia Carbon Brick---Refractory Brick---Refractory Material---Changxing Refractory

|

| Alumina Magnesia Carbon Bricks are used in Ladle Sidewall and Bottom impact areas. |

Introduction:

Alumina Magnesia Carbon Bricks is made from high quality bauxite, corundum and fused magnesia. It is formulated with very high purity alumina and magnesia.

Advantages:

It has low thermal conductivity, good isolation ability, and appropriate residual expansion

Application:

Alumina Magnesia Carbon Bricks are used in Ladle Sidewall and Bottom impact areas.

Henan Xinmi Changxing Refractory Material Co., Ltd. Located in Henan Province,China.ChangXing's product portfolio covers shaped products such as refractory materials,refractory brick, refractory castable,refractory nozzle, ceramic fiber, slide gate, etc; unshaped products including repair, construction and casting mixes and mortars.exported to more than 20 countries, such as Thailand, Indonesia, Pakistan, Saudi Arabia, South Africa, Turkey, Iran, Iraq and so on.

Content source:

http://www.yilongrefractory.com/AllProductOneServlet?id1=1&id=4

E-mail:sales8@chinaelong.com

2016年12月9日星期五

Magnesia aluminum refractories is Basic Refractories

Magnesia alumina brick refractories of basic refractories:

Ladle steel industry is an important and indispensable equipment, as refractory ladle lining, several major changes. Used to be traditional by sintering of clay bricks and third class alumina brick, the refractory material shows poor chipping resistance and corrosion resistance during use, low life, an average of only 10 times, dried treatment can only reach about 20 times. With the development of steelmaking technology, refining the molten steel to improve the outer retaining ladle lining refractories requirements in the early years of the 20th century that is, once the application as a whole

Cast Mg-Al quality ladle lining material. This lining integrity, and significantly improve the service life, but there are baked ladle long time, there are more serious dregs phenomenon for medium and small mills no special equipment most circumstances, unpacking difficult. To compensate for this deficiency, then the successful application of aluminum-magnesia unfired brick. The lining brick building is easy to assemble, baking time is short and easy unpacking, but still easy to kill slag and chipping resistance is poor. On this basis, in order to overcome the problem of aluminum-magnesia unfired brick ladle lining easy cat slag around the corner late he has not developed the aluminum-magnesia carbon brick, replacing the aluminum-magnesia unfired brick. The material combines the properties of aluminum-magnesia material and carbonaceous material. The main advantages of aluminum-magnesia carbon brick does not have: no cracks between the blocks melt loss, has good resistance to thermal shock resistance and slag ability to overcome the structural steel and slag penetration flaking, significantly improved service life and so on. Because the article is not burning or low-temperature firing, save energy, reduce costs, economic efficiency is very obvious, it attracted people's attention.

China advised in the 20th century, it began with bauxite and magnesite (or light burned MgO) magnesia aluminate spinel raw materials research. In recent years, also carried out a series of studies preparation of magnesia spinel products combine technology, achieved a lot, but the performance has been excellent in high purity products suffer from a high degree of firing is very limited. Domestic activity spinel powder was used. The ultra-high temperature firing process overseas (1 850c) down to 1 660C. But for the average coal-fired furnace refractory general terms, it is still difficult to achieve. To this end, the domestic refractory experts and scholars made active magnesia aluminum gum as a binding agent, was studied with the active Mg-Al gum as binding agent and high-purity magnesia brick magnesia brick spinel combination of performance, the use of magnesia aluminum adhesive activity, both make excellent performance products fired at 1 550 ℃, such as the advanced products in firing ordinary refractory kiln plant in Shanghai possible.

Through active lime kiln back to actual production, research and development of magnesia aluminate spinel unfired brick. Use show, developed spinel unburned brick in the active lime kiln firing service life of more than one year. For a long time, directly from the dry combination of magnesia-chrome brick with excellent slag resistance and corrosion resistance, it is used in large alkaline rotary kiln Pu left. Currently the most widely used range of the steel industry, most of the largest refractory Mg - Al system is unshaped refractory, accounting for about 85% of the unshaped refractories of total production, it is widely used in the converter, ladle, iron package, furnace and blast, virtually all metallurgical thermal equipment.

Spinel has a high melting point, small thermal expansion, low thermal stress, thermal vibration stability, and it has a more stable chemical properties of alkaline slag has a strong resistance, aluminum-magnesia do not burn brick core point to be used, is one of the key substances to improve life. Due to the gradual maturity in recent years, synthetic spinel technology, the use of synthetic spinel materials directly produce good ladle brick as possible, so that it can significantly improve the properties.

Quality spinel is one of the key issues related to the inter-spinel bricks can achieve the proper effect. By introducing the screening laboratory tests and related information, the magnesia-rich spinel 20% to 30% of its corrosion resistance, structural spalling resistance and thermal shock properties are better. But ladle conditions are more factors in the production operation, the amount of added spinel requirements should be 30% to 40% is more reasonable. Therefore, in brick-making process, in addition to producing a good artificial spinel added, we must also note the addition of fused magnesia powder and alumina powder, so that the secondary spinel regenerated during use. Thereby improving bricks tomb of quality performance parts for the control of harmful impurities in particular low-melting material was Na20 and K2O content, the choice of raw materials need special attention exhausted.

Spinel (also known as spinel) has the formula MgO-Al2O3, containing Mg0 was 28.3%, Al2O3 71.7%. Spinel is only Mg0-Al2O3 binary system phase diagram of an intermediate compound, melting at 2 135 C.

Henan Xinmi Changxing Refractory Material Co., Ltd. Located in Henan Province,China.ChangXing's product portfolio covers shaped products such as refractory materials,refractory brick, refractory castable,refractory nozzle, ceramic fiber, slide gate, etc; unshaped products including repair, construction and casting mixes and mortars.exported to more than 20 countries, such as Thailand, Indonesia, Pakistan, Saudi Arabia, South Africa, Turkey, Iran, Iraq and so on.

Ladle steel industry is an important and indispensable equipment, as refractory ladle lining, several major changes. Used to be traditional by sintering of clay bricks and third class alumina brick, the refractory material shows poor chipping resistance and corrosion resistance during use, low life, an average of only 10 times, dried treatment can only reach about 20 times. With the development of steelmaking technology, refining the molten steel to improve the outer retaining ladle lining refractories requirements in the early years of the 20th century that is, once the application as a whole

Cast Mg-Al quality ladle lining material. This lining integrity, and significantly improve the service life, but there are baked ladle long time, there are more serious dregs phenomenon for medium and small mills no special equipment most circumstances, unpacking difficult. To compensate for this deficiency, then the successful application of aluminum-magnesia unfired brick. The lining brick building is easy to assemble, baking time is short and easy unpacking, but still easy to kill slag and chipping resistance is poor. On this basis, in order to overcome the problem of aluminum-magnesia unfired brick ladle lining easy cat slag around the corner late he has not developed the aluminum-magnesia carbon brick, replacing the aluminum-magnesia unfired brick. The material combines the properties of aluminum-magnesia material and carbonaceous material. The main advantages of aluminum-magnesia carbon brick does not have: no cracks between the blocks melt loss, has good resistance to thermal shock resistance and slag ability to overcome the structural steel and slag penetration flaking, significantly improved service life and so on. Because the article is not burning or low-temperature firing, save energy, reduce costs, economic efficiency is very obvious, it attracted people's attention.

China advised in the 20th century, it began with bauxite and magnesite (or light burned MgO) magnesia aluminate spinel raw materials research. In recent years, also carried out a series of studies preparation of magnesia spinel products combine technology, achieved a lot, but the performance has been excellent in high purity products suffer from a high degree of firing is very limited. Domestic activity spinel powder was used. The ultra-high temperature firing process overseas (1 850c) down to 1 660C. But for the average coal-fired furnace refractory general terms, it is still difficult to achieve. To this end, the domestic refractory experts and scholars made active magnesia aluminum gum as a binding agent, was studied with the active Mg-Al gum as binding agent and high-purity magnesia brick magnesia brick spinel combination of performance, the use of magnesia aluminum adhesive activity, both make excellent performance products fired at 1 550 ℃, such as the advanced products in firing ordinary refractory kiln plant in Shanghai possible.

Through active lime kiln back to actual production, research and development of magnesia aluminate spinel unfired brick. Use show, developed spinel unburned brick in the active lime kiln firing service life of more than one year. For a long time, directly from the dry combination of magnesia-chrome brick with excellent slag resistance and corrosion resistance, it is used in large alkaline rotary kiln Pu left. Currently the most widely used range of the steel industry, most of the largest refractory Mg - Al system is unshaped refractory, accounting for about 85% of the unshaped refractories of total production, it is widely used in the converter, ladle, iron package, furnace and blast, virtually all metallurgical thermal equipment.

Spinel has a high melting point, small thermal expansion, low thermal stress, thermal vibration stability, and it has a more stable chemical properties of alkaline slag has a strong resistance, aluminum-magnesia do not burn brick core point to be used, is one of the key substances to improve life. Due to the gradual maturity in recent years, synthetic spinel technology, the use of synthetic spinel materials directly produce good ladle brick as possible, so that it can significantly improve the properties.

Quality spinel is one of the key issues related to the inter-spinel bricks can achieve the proper effect. By introducing the screening laboratory tests and related information, the magnesia-rich spinel 20% to 30% of its corrosion resistance, structural spalling resistance and thermal shock properties are better. But ladle conditions are more factors in the production operation, the amount of added spinel requirements should be 30% to 40% is more reasonable. Therefore, in brick-making process, in addition to producing a good artificial spinel added, we must also note the addition of fused magnesia powder and alumina powder, so that the secondary spinel regenerated during use. Thereby improving bricks tomb of quality performance parts for the control of harmful impurities in particular low-melting material was Na20 and K2O content, the choice of raw materials need special attention exhausted.

Spinel (also known as spinel) has the formula MgO-Al2O3, containing Mg0 was 28.3%, Al2O3 71.7%. Spinel is only Mg0-Al2O3 binary system phase diagram of an intermediate compound, melting at 2 135 C.

Henan Xinmi Changxing Refractory Material Co., Ltd. Located in Henan Province,China.ChangXing's product portfolio covers shaped products such as refractory materials,refractory brick, refractory castable,refractory nozzle, ceramic fiber, slide gate, etc; unshaped products including repair, construction and casting mixes and mortars.exported to more than 20 countries, such as Thailand, Indonesia, Pakistan, Saudi Arabia, South Africa, Turkey, Iran, Iraq and so on.

订阅:

博文 (Atom)

Refractory Material, Fire Bricks, Refractory Manufacturer, China Refractory - CX Refractories

Refractory Material, Fire Bricks, Refractory Manufacturer, China Refractory - CX Refractories

-

refractory materials Common types of ladle refractories: (1) Clay refractory brick , clay brick A12O3 content is generally between 30% ...

-

Refractory materials There are three key drivers behind the evolution of refractories: maintaining improved glass quality; economic requ...

-

blast furnace refractory lining material 1.Temperature. The damaged performance of high temperature to fire brick: (1)Erosion. When t...