|

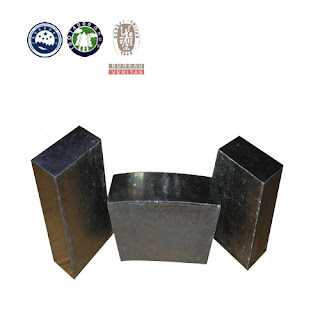

| Refractories for electric furnace |

Electric furnace cover with refractory brick require good thermal shock resistance, high temperature splash on the erosion resistance, as well as good integrity, solid structure is not crack and so on.

Electric furnace lid with refractory material development trend is: brick - prefabricated block - the overall pouring, the specific conditions of different countries, the use of materials are not the same.

For alkaline firebrick cover, electric tile with magnets. In order to ensure the stability of the furnace cover structure and reduce the deformation and peeling of magnesia, the use of iron plaster or masonry insert iron. As the metal induced current (especially high power electric furnace refractories cover), the formation of local overheating to non-magnetic steel brick, on the other hand pure magnesia brick linear expansion coefficient is too large, the amount of small.

In addition, the whole pouring the lid. The use of the overall casting furnace lid to promote the life of the furnace to further improve. After the water is cooled, the electrode is also water-cooled around the electrode, and the high-alumina ultra-low cement castable containing 3% Cr2O3 is added from the material and the stainless steel fiber is added. The furnace cover is used in the case of slightly repaired 594 furnace and service life is 4 times than before.

Article source:

Refractories for electric furnace roof

E-mail:sales8@chinaelong.com